Enhancing Vacuum Furnace Performance

with Carbon Composite Technology

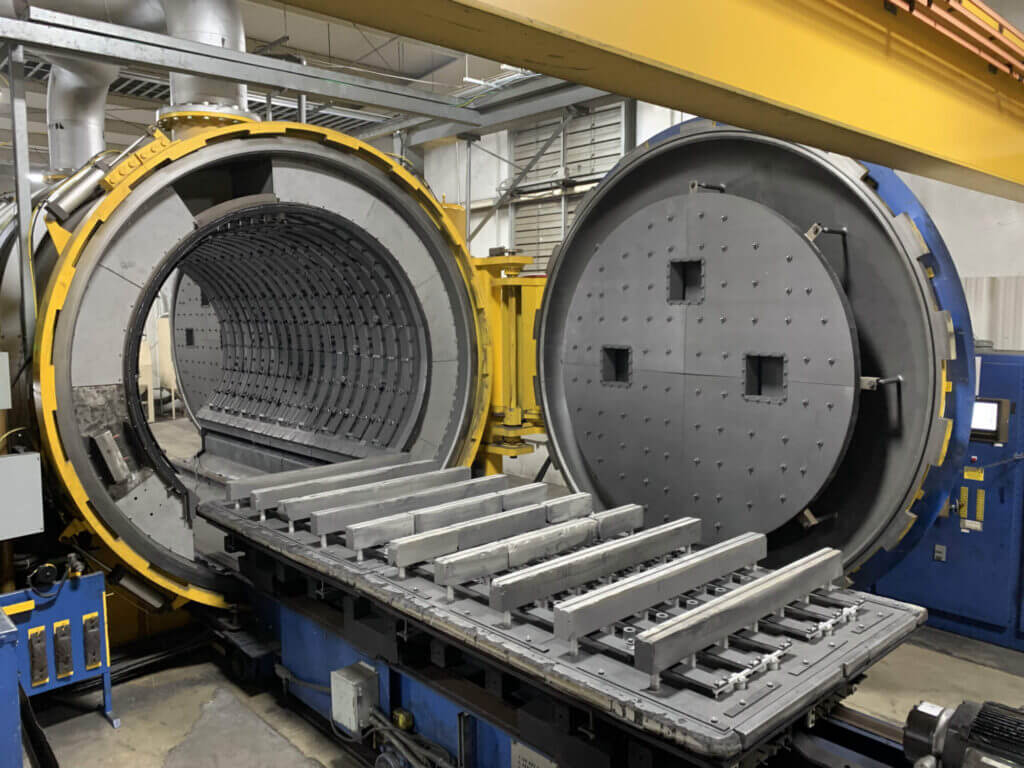

The vacuum furnace industry relies on high-performance materials that can withstand extreme temperatures, provide excellent thermal insulation, and ensure precision in heat treatment processes. Carbon composites and graphite-based products are at the heart of modern vacuum furnace technologies, offering superior thermal properties, durability, and efficiency. These materials are critical in maintaining controlled atmospheres, optimizing energy use, and extending equipment lifespan, making them essential for industries such as aerospace, automotive, metallurgy, and more.

We offer a range of specialized products,designed to meet the demanding requirements of vacuum furnace operations. Our products provide exceptional thermal management, reduce energy loss, and ensure reliable performance in high-temperature environments.

Products for the Vacuum Furnace Industry

We provide a comprehensive suite of carbon composite and graphite-based products specifically tailored for vacuum furnace applications:

Foil Insulation Board

C/C Nuts and Bolts

C/C L & U Angles

C/C Fixtures

Customized Insulation

Graphite Felt

C/C Plates

CFC Insulation Board

Applications of Carbon Composites Vacuum Furnace Industry

Our products support a range of critical applications within the vacuum furnace industry:

Thermal Insulation

Our insulation boards and graphite felt are used to create highly efficient thermal barriers in vacuum furnaces, reducing energy loss and improving process control. These materials are essential for maintaining consistent temperatures and ensuring high-quality heat treatments.

Structural Support

C/C L & U angles and C/C plates provide strong yet lightweight structural support for various furnace components, helping maintain stability and performance during high-temperature processes.

Material Handling

C/C fixtures and plates are used to hold and secure materials within the furnace during heat treatment, ensuring precision and minimizing contamination in high-temperature environments.

Temperature Control

C/C heaters deliver uniform heat distribution, ensuring consistent temperature control in vacuum furnace applications such as sintering, brazing, and annealing.

Benefits of Carbon Composite Solution in Vacuum Furnaces

Carbon composites offer numerous advantages for the aerospace industry:

Our carbon composite insulation boards, graphite felt, and heaters provide exceptional thermal management, ensuring that furnaces operate efficiently at high temperatures with minimal energy loss.

Carbon composites, such as C/C plates and L & U angles, are lightweight yet highly durable, offering resistance to thermal shock, corrosion, and wear in extreme environments.

Our customized insulation boards and fixtures can be tailored to specific furnace designs and operational requirements, ensuring that your vacuum furnace operates at peak performance with precise thermal control.

By utilizing carbon composite fixtures, plates, and heaters, manufacturers can optimize the efficiency of heat treatment processes such as annealing, sintering, and brazing, leading to improved product quality and reduced cycle times.

Carbon composite materials are highly resistant to wear, thermal degradation, and oxidation, meaning they last longer and require less frequent replacement, reducing downtime and overall maintenance costs.

Solutions for the Vacuum Furnace Industry

We understand the critical role vacuum furnaces play in industries such as aerospace, automotive, and metallurgy. Our carbon composite and graphite solutions are designed to enhance furnace performance, improve energy efficiency, and provide reliable thermal insulation and structural support. From C/C fixtures and insulation boards to graphite felt and C/C heaters, our materials are engineered to meet the demands of high-temperature processes.

Our team works closely with manufacturers to develop customized solutions that meet the unique requirements of their vacuum furnace operations. Whether you need enhanced thermal insulation, precise temperature control, or durable components capable of withstanding extreme conditions, we have the expertise to deliver tailored products that optimize your production processes.

By leveraging the exceptional properties of carbon composites, we help aerospace companies optimize their designs for reduced weight, increased performance, and greater durability. Our solutions are tailored to fit the specific needs of aerospace applications, ensuring that you achieve the highest levels of performance while minimizing operational costs.

Partner with Us: Advanced Carbon Composite Solutions for Vacuum Furnaces

By choosing our carbon composite and graphite-based products, you gain access to state-of-the-art materials that improve the efficiency and durability of your vacuum furnace systems. Whether you're looking to upgrade your insulation, enhance structural support, or optimize heat distribution, we provide solutions that help you achieve higher performance, lower energy costs, and extend equipment lifespan.